Diamox ITO & Index Matched Diamox ITO Coatings

Diamond Coatings, a privately-owned company, is a recognised leader in the production of vacuum coatings which includes the DIAMOX Indium Tin Oxide (ITO) range. The ITO coating is a highly conductive transparent coating which is available vacuum deposited onto all glass types or plastic / polymer substrates.

Diamox ITO Coating is used in a wide range of applications including electromagnetic/radiofrequency (EMI/RFI) shielding, electrostatic protection (both anti-static and electro-static discharge), transparent heated filters for electronic displays and the active component in touch screens.

Diamond Coatings supplies a large number of OEM’s in the electronic and electrical industries in Europe, USA and Asia.

Capability

The Company has a reputation for innovation having developed designed and built its own coating plants to vacuum deposit our Diamox Indium Tin Oxide onto nearly all substrate types.

The Diamox ITO deposition process is carried out both at high temperatures for very low sheet resistances on glass, but also and uniquely Diamox ITO Coatings are also vacuum deposited at low temperatures in a vacuum, allowing a variety of plastics including polycarbonate, acrylic and polyester as well as glass to be vacuum deposited with our high-quality Diamox ITO Coating range.

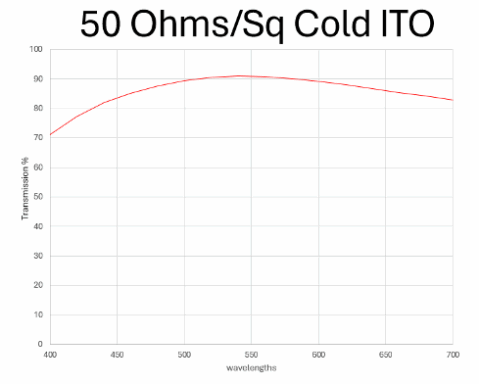

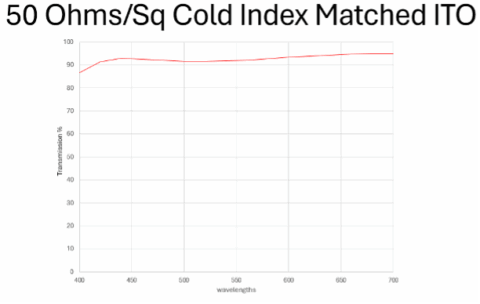

Diamox ITO Coatings can also be offered with Index Matching and additional optical layers to enhance and further improve the light transmission and optical performance.

A flexible system for handling the substrates and options of a number of different vacuum coatings plants in our manufacturing facilities allows both flat and curved surfaces, as well as a range of injection moulded shapes to be vacuum coated.

Diamox ITO Coatings can be vacuum deposited to customers free issue parts. Alternatively, Diamond can offer complete supply of nearly all substrate types to drawings or stated design parameters.

Substrates can be screen printed in standard or conductive inks and can also incorporate anti-glare, anti-reflective and scratch resistant features.

Performance Characteristics

Durability

Diamox coated polycarbonate has been subjected to the following accelerated tests:

- Thermal Cycling to MIL STD C 48497, 4.5.4.1. (5h at –60 oC followed by 5h at +70 oC)

- Salt Solution to MIL STD C48497, 4.5.5.2. (24h immersion in 5% NaCl solution)

- Humidity Cycling to MIL STD C 48497 (24h 50 oC 95%humidity)

- Coating adhesion was tested to ASTM D 3359-83 method B

There was no evidence of optical degradation or coating adhesion and only a small change in sheet resistance on thermal cycling.

Sheet Resistance

Sheet resistances are available from 2.5 to1000 ohms/square.

The standard tolerance is +/-20%

Shielding Effectiveness

| 100 | 1k | 10k | 1M | 10M | 100M | 1G | |

| 10 ohms/sq | 70 | 69 | 76 | 58 | 57 | 35 | 26 |

| 20 ohms/sq | 66 | 69 | 75 | 69 | 59 | 28 | 23 |

Substrate Availability

Glass and Ceramic

Diamox ITO Coatings can be vacuum deposited onto all standard glass types as well as special optical glasses and other substrate such as silicon wafers. Diamond Coatings can vacuum deposit customer own substrate, alternatively offer full supply of substrates and vacuum coatings onto thermally toughened and chemically strengthened glasses, Borosilicate. BK7. Quartz, Sapphire along with Alumino-Silicate Glasses such as Corning Gorilla Glass and AGC Dragontrail Glass.

Plastic & Polymer

Diamond Coatings can vacuum deposit Diamox ITO Coatings onto many plastics and polymers, these include but are not limited to: Polycarbonate, Acrylic as well as PET and PEN Films.

Diamond Coatings can source and offer full supply of both substrates and vacuum deposited coatings to our customers targeted requirements.

ITO & Index Matched ITO Coatings Enquiry

The following information about your project will help Diamond Coatings to quickly learn about your project and subsequently respond to your enquiry. Please complete as accurately as possible.