Coated Glass Factories

At Diamond Coatings, we’re not just about providing high-quality coated glass solutions; we’re also committed to manufacturing excellence

All orders placed between December 20th and January 2nd will be processed on January 3rd

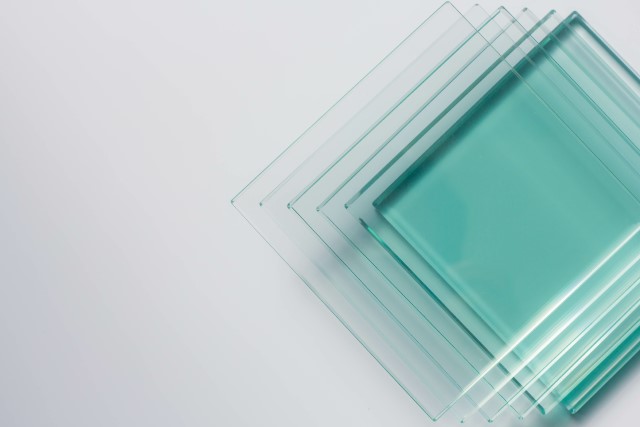

ITO coating on glass substrates

Within the many technological advancements of recent decades, there exists a subtle yet transformative fusion – Indium Tin Oxide (ITO) coatings on glass substrates – an area where Diamond Coatings emerges as a leading supplier. ITO deposited onto glass offers both transparency and conductivity, unlocking a realm of possibilities across diverse industries and applications.

At the heart of Diamond Coatings’ expertise lies the method of depositing ITO coatings onto glass substrates with precision and finesse. This process, mastered through years of innovation and continuous refinement, results in thin, transparent layers that exhibit remarkable electrical conductivity while preserving the inherent transparency of glass.

Operating from our purpose built, state of the art facility in Phoenix, Arizona, Diamond Coatings have established themselves as true market leaders for ITO coating on glass substrates.

But why the emphasis on ITO coatings specifically on glass substrates? The answer lies in the unparalleled synergy between these materials. Glass, used for its optical clarity and structural integrity, can be paired with ITO, a transparent conductor, to form a union that revolutionizes touch-sensitive technologies, optical devices, and beyond.

Coated glass that remains clear but now has conductive qualities. Why would you need such conductive glass? We list some of the numerous applications that utilise ITO glass.

The applications of ITO coated glass substrates span a vast spectrum, with Diamond Coatings at the forefront of innovation. One of the most prominent uses lies in touch sensitive interfaces, particularly in the application of smartphones and tablets. These sleek, responsive screens owe their functionality to the capacitive magic provided by ITO coated glass, where every gentle touch translates into digital action with precision and speed.

In the world of architectural glazing there has been a transformation through ITO coated glass substrates. Smart windows and interactive surfaces embedded within building facades or interior designs leverage the transparency and conductivity of these coatings. They not only enhance aesthetics but also offer functionalities like dynamic shading and touch responsive surfaces, revolutionizing the concept of modern architecture.

The advancements in medical technology embrace the versatility of ITO coated glass substrates. From diagnostic equipment panels to touch sensitive displays in medical devices, the precision and reliability offered by these coatings aid healthcare professionals in delivering efficient care without technological hindrances.

The automotive industry also experiences the impact of ITO coated glass, particularly in the development of heads-up displays (HUDs) and touch sensitive interfaces within vehicles. These interfaces offer drivers enhanced functionality without compromising visibility or safety, thanks to the seamless integration of ITO coated glass substrates.

Diamond Coatings’ expertise lies not only in the application of ITO coatings but also in our commitment to innovation and quality. The manufacturing process from our purpose built facility in Phoenix, executed with meticulous care, ensures uniformity, durability, and optimal performance across their range of ITO coated glass substrates, catering to the exacting standards of various industries.

The deposition of ITO coatings onto glass substrates, manufactured with Diamond Coatings’ expertise, opens a gateway to a future where transparency and conductivity converge seamlessly. The applications across industries, from consumer electronics to architectural glass structures and healthcare, highlight the transformative impact of ITO coated glass substrates in shaping a world where technology and aesthetics harmonize effortlessly.

Do you have a project that requires ITO glass substrates? We would love to hear from you – a member of our technical team will be happy to answer any questions that you may have – Get in touch today!

At Diamond Coatings, we’re not just about providing high-quality coated glass solutions; we’re also committed to manufacturing excellence

Our ITO films provide a transparent and conductive layer that enables seamless touch interaction while maintaining optimal clarity

Advancements in coating technology have led to the development of highly effective scratch-resistant coatings that enhance the durability and longevity of acrylic.

If your project requires a material that can effectively conduct electricity, several excellent alternatives to duct tape are available

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.