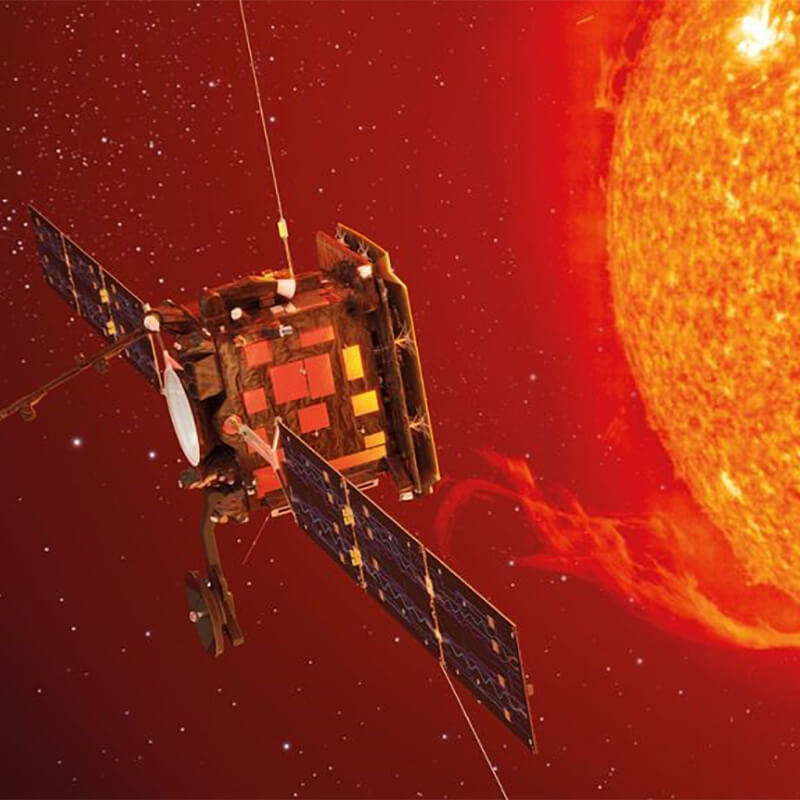

THE SOLAR ORBITER

This exciting project allowed Diamond Coatings to work with the European Space Agency, exploring and observing the sun with the Solar Orbiter.

Buckle up… It’s a HOT one!

The Solar Orbiter will offr views of the sun that have simply never been encountered before, experiencing sunlight 13 times more powerful that that of the Earth’s orbit.

Diamond Coatings applied a custom coating to all of the non-facing white panels to prevent electrostatic discharge and keeping conductivity sufficient at -120C.

The Orbiter was coated in a pigment made from bone, with the resulting carbon / ceramic being excessively durable and under UV and temperature cycling was shown to be highly stable.

A white silicate layer was introduced as an overcoat as compensation for the differing temperatures of the hot aluminium on the inward face of the panels and the outer panels facing the cold vacuum of space.

The initial SolarWhite coating was co-developed between University College Dublin in Ireland and ENBIO. Not all of the SolarWhite components were sun facing and would reach temperatures as low as -120°C. At such a low temperature, surface conductivity of ceramic would decrease which may have caused potential risk for charging. A possible result would be electrostatic discharge that could jeopardise an electrical system on the craft.

Without the help of Diamond Coatings and their application of the conductive ITO coating on the SORA (Stood-Off Radiator Assembly) panels, the Solar White coating would not have performed as intended, putting key instruments at risk. The collaboration was facilitated by Diamond Coating’s flexibility and willingness to support us with our tight deadlines and the scrutiny that goes with such a big project. Barry Twomey, ENIBO CTO

can we help You?

If you have any questions about our extensive range of services and products and require more detailed information, please get in touch now.