Enhance Your Garmin Nav 6 with AR Film

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

For orders placed online please contact us for an accurate shipping quote, sorry for any inconvenience.

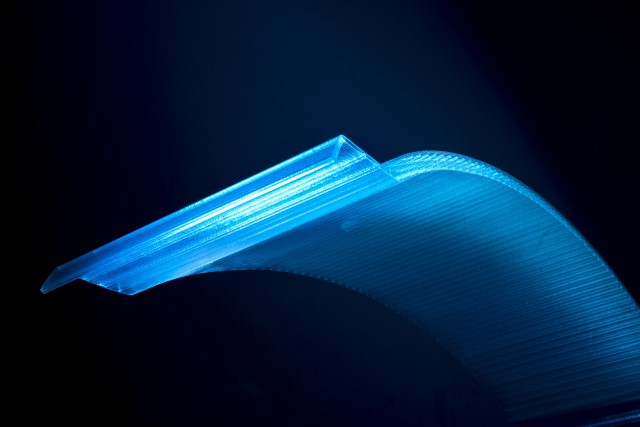

The applications of advanced Plastic Coatings

Plastics have become the backbone of countless industries, offering lightweight, versatile, and cost-effective solutions for a wide range of products. But what if we could enhance these already remarkable materials, unlocking new possibilities and applications? That’s precisely where advanced coatings step in, transforming ordinary plastics into high-performance powerhouses.

At Diamond Coatings, we’re at the forefront of this exciting revolution, specializing in the application of cutting-edge coatings that empower plastics to achieve extraordinary feats. In this blog post, we’ll delve into the world of advanced plastic coatings, with a special emphasis on Indium Tin Oxide (ITO), a true game-changer in the realm of electronics and beyond.

Why Give Plastics a Boost?

While plastics are undeniably useful, they do have some limitations. Coatings address these challenges head-on:

ITO: The Star of the Show

Among the various advanced coatings available, Indium Tin Oxide (ITO) stands out for its unique combination of transparency and electrical conductivity. This remarkable material has revolutionized several industries:

Beyond ITO: A Spectrum of Possibilities

While ITO takes center stage, other advanced plastic coatings cater to diverse needs:

Diamond Coatings: Your Trusted Partner

At Diamond Coatings, we’re not just experts in ITO coatings; we offer a comprehensive range of advanced coating solutions for plastics. Our team of skilled technicians and state-of-the-art equipment ensure that your plastic components receive the highest quality coatings tailored to your specific needs.

Whether you’re looking to enhance the functionality, durability, or aesthetics of your plastic products, we have the expertise and experience to help you achieve your goals. Contact us today to explore the limitless possibilities of advanced plastic coatings.

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

At Diamond Coatings, we provide the foundational transparent conductive coatings that are absolutely essential for capacitive switches

An ITO company fundamentally deals with the precise deposition of Indium Tin Oxide onto various substrates

Glass offers transparency and clear views. But what if it could also conduct electricity, integrating power and data directly into a transparent surface?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.