Enhance Your Garmin Nav 6 with AR Film

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

For orders placed online please contact us for an accurate shipping quote, sorry for any inconvenience.

The Applications of Transparent Conductive Film

Consider the presence of screens and sensors in our daily lives – from the touch interface of your coffee machine to the expansive digital signage at an airport. Many of these modern marvels owe their functionality to a discreet yet vital material: transparent conductive film. This advanced film, often made by coating a plastic substrate with Indium Tin Oxide (ITO), uniquely combines optical clarity with electrical conductivity.

At Diamond Coatings, we are experts in the precision manufacture and supply of these high-performance films. The range of applications for transparent conductive film is vast and continually expanding, pushing the boundaries of design and interaction across numerous industries.

What is Transparent Conductive Film?

At its core, transparent conductive film is typically a flexible plastic substrate (like PET or polycarbonate) that has been coated with a Transparent Conductive Oxide (TCO). The most common and effective TCO is Indium Tin Oxide (ITO).

The unique properties of ITO allow the film to transmit light and conduct electricity. This dual functionality is the key differentiator. Unlike opaque metal conductors or insulating clear plastics, transparent conductive film offers both attributes simultaneously, enabling a wide array of revolutionary products.

How it’s Made: Diamond Coatings’ Precision Process

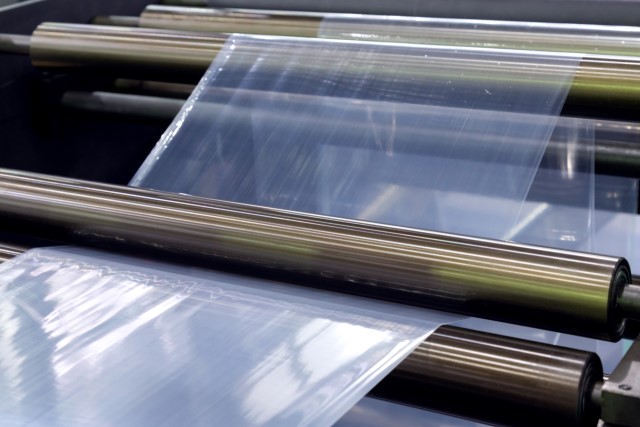

The creation of a high-quality transparent conductive film requires sophisticated manufacturing techniques. At Diamond Coatings, we employ advanced vacuum deposition methods to precisely apply the ITO layer onto the plastic film.

This process ensures:

The result is a flexible, durable film that can be integrated into various products, maintaining visual integrity while adding crucial electrical functionality.

Key Applications

The versatility of transparent conductive film makes it an indispensable component across a diverse range of high-tech applications:

Flexible Touch Panels: The most obvious application. The ITO-coated film forms the crucial sensing layer in flexible and foldable smartphones, tablets, and wearable devices, allowing for multi-touch gestures and robust, shatter-resistant designs.

Interactive Kiosks & Signage: Provides the touch interface for public information terminals, retail displays, and interactive digital signage.

Capacitive Touch: The fundamental technology behind most modern touchscreens relies on the ITO film’s ability to detect changes in an electrical field caused by a finger’s touch.

Wearable Technology: From smart fabrics with integrated sensors to health monitoring patches, transparent conductive film enables electronics that conform to the human body.

Bendable & Rollable Displays: Crucial for the next generation of OLED and other flexible display technologies, allowing screens to be curved, rolled up, or folded.

Sensitive electronic equipment often requires protection from electromagnetic interference (EMI) and radio frequency interference (RFI) to prevent malfunction. Transparent conductive films can be integrated into viewing windows or enclosures, providing effective shielding while maintaining visibility. This is vital in medical devices, aerospace cockpits, and secure communication systems.

The electrical conductivity of the ITO layer allows it to be used for resistive heating. By passing a current through the film, it generates gentle heat. This is used in:

Anti-Fogging/De-icing: Preventing condensation or ice build-up on transparent plastic windows, visors, or display panels in cold or humid environments (e.g., freezer doors, specialised vehicle windows, motorcycle helmet visors).

Thermal Control: Maintaining optimal operating temperatures for sensitive components.

Transparent Electrodes: Used in various sensor designs and optoelectronic devices, including certain types of flexible solar cells, where the film acts as a current collector without obstructing light absorption.

Diamond Coatings: Your Partner in Transparent Conductivity

As a leading supplier of transparent conductive films, Diamond Coatings offers a comprehensive range of solutions tailored to specific performance requirements. Our deep technical expertise and commitment to quality ensure that our films provide the optimal balance of transparency, conductivity, and durability for even the most demanding applications.

If your project requires the innovative capabilities of transparent conductive film, our team of experts is ready to discuss your needs and provide a bespoke coating solution that powers your next breakthrough.

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

At Diamond Coatings, we provide the foundational transparent conductive coatings that are absolutely essential for capacitive switches

An ITO company fundamentally deals with the precise deposition of Indium Tin Oxide onto various substrates

Glass offers transparency and clear views. But what if it could also conduct electricity, integrating power and data directly into a transparent surface?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.