For orders placed online please contact us for an accurate shipping quote, sorry for any inconvenience.

Diamond Coatings USA ITO Coatings Supplier

Combining innovative ideas and years of experience with ultra-modern technology and state-of-the-art coating techniques, Diamond Coatings Inc have successfully established themselves as a market-leading US ITO coatings supplier.

DC US ITO Coatings Supplier

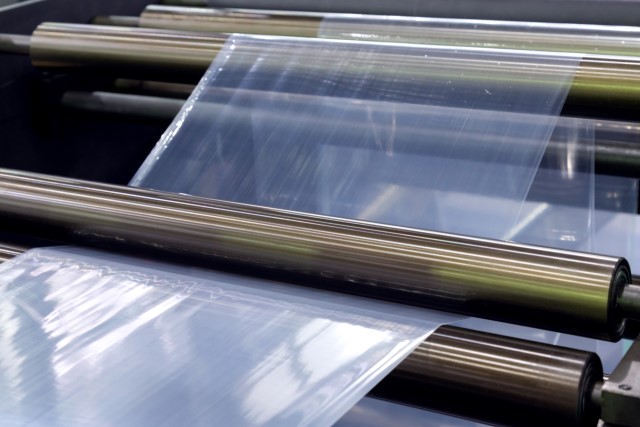

Operating vacuum coating plants designed & built to their own specifications within ultra-modern facilities in Phoenix, Arizona, Diamond Coatings Inc offer a diversity of premium-quality ITO and Index Matched ITO coatings.

Highly conductive, transparent and boasting excellent electronic, opto-electronic and optical properties, our ITO coatings are ideal for a practically unlimited range of research & development, science, military, entertainment and other commercial applications including, among others:

- Energy Efficient Windows, Photovoltaic Cells and Gas Sensors

- Plasma, Field Emission, LCD and Electrochromic/Electroluminescent Displays

- Touch Panels/Screens (Resistive and Capacitive) and ITO Microscope Slides & Cover Slips

- Heat Reflective Coatings, Heated Display (Optically Clear) Filters and ITO Coated PEN/PET Films

- Electrostatic Dissipation, EMI/RFI Shielding and More

We currently offer two distinct ITO coating options:

Custom Diamox ITO – Applied to varying glass or plastic (polyester, acrylic or polycarbonate) substrates via low-temperature vacuum deposition, our highly conductive, transparent Custom Diamox ITO coating can be produced with a coating capacity of 4m/sq across a drum coater system and a range of sheet resistances (depending on coat thickness).

Thoroughly tested (MIL STD 48497), Custom Diamox ITO coatings showed no evident reductions in adhesion/sheet resistance and no optical degradation when subjected to thermal & humidity cycling and salt spray.

Resistant to moisture/water penetration, flaking and peeling; crazing, cracking and delamination, Custom Diamox ITO coatings offer high RFI/EMI shielding effectiveness (26dB at 1GHz and 58dB at 1MHz; tested to MIL STD 215) and typical (for 20ohms/sq coatings on glass/polycarbonate and wavelengths between 525 and 600 nm) respective peak light transmissions of 87/81 per cent.

Flexibility within our substrate handling system permits coating of flat, shaped, injection-molded and free issue parts. We can also provide fully machined parts (glass or plastic) and Diamox coatings can be finely etched to create precise conductor paths.

Diamox+ Index-Matched ITO – Combining layers of metal oxides and quartz*, this multi-layer coating offers all characteristics/properties of Diamox ITO while providing for index-matched coatings.

*To suppress undesirable reflection and enhance transmission, the thickness of this quartz layer is subject to careful control.

Offering much better peak light transmissions (92/82 per cent respectively for 20ohms/sq coatings on one side of glass/polycarbonate substrates and wavelengths between 525 and 600 nm) than standard ITO coatings, Diamox+ coatings can be applied to plastic/glass substrates up to a coating capacity of 4m/sq.

Call Our Experts

We have designed many of our Multi-Layer AR (Anti-reflection), ITO and Index-Matched ITO coatings specifically to meet customer specifications (transmission/reflection graphs available upon request).

Are you working on an application with specific optical requirements? Our technical team will be more than happy to assist you by designing/recommending the most suitable coating for your purpose – call them on Tel:(480) 999-3456 now to get started.

Please note: If you are getting in touch from anywhere outside the United States, please dial this number instead: 001 (480) 999-3456.