Enhance Your Garmin Nav 6 with AR Film

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

For orders placed online please contact us for an accurate shipping quote, sorry for any inconvenience.

Why Would You Need Conductive Plastic?

Conductive plastic is a revolutionary material that combines the versatility of plastic with the conductive properties of metals. But why would you choose conductive plastic over traditional materials? At Diamond Coatings, we specialize in using Indium Tin Oxide (ITO) coatings to create high-performance conductive plastics, unlocking a new era of possibilities across various industries.

Metals have long dominated the realm of electrical conductivity. However, they come with limitations:

Introducing Conductive Plastic

Conductive plastic offers a compelling alternative, addressing the limitations of traditional materials:

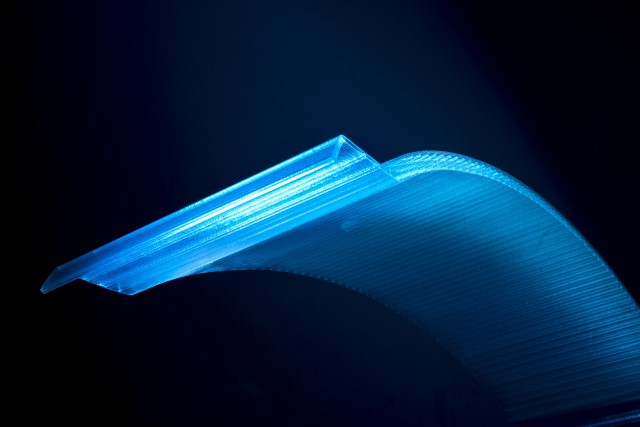

But how do we make plastic conductive? At Diamond Coatings, we utilize a remarkable material called Indium Tin Oxide (ITO). This transparent material boasts exceptional electrical conductivity, making it the perfect candidate for transforming plastic.

Our process involves a technique called sputtering. Think of it as a high-tech paint job for plastic. We bombard a target material (ITO) with high-energy particles, causing it to release atoms that meticulously coat the plastic surface. The result? A flawlessly bonded, ultra-thin layer of ITO that grants the plastic exceptional conductivity without compromising its inherent benefits like lightweight design and flexibility.

Applications of Conductive Plastic

The unique properties of conductive plastic open doors to a world of innovative applications:

Diamond Coatings Conductive Plastic

At Diamond Coatings, we’re more than just a supplier – we’re your innovation partner. We offer a comprehensive range of conductive plastic solutions with ITO coatings, tailored to your specific needs. Our team of experts are dedicated to guiding you through the exciting world of conductive plastics and helping you integrate them seamlessly into your next project.

Contact Diamond Coatings today and let’s discuss your conductive plastic requirements.

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

At Diamond Coatings, we provide the foundational transparent conductive coatings that are absolutely essential for capacitive switches

An ITO company fundamentally deals with the precise deposition of Indium Tin Oxide onto various substrates

Glass offers transparency and clear views. But what if it could also conduct electricity, integrating power and data directly into a transparent surface?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.