Enhance Your Garmin Nav 6 with AR Film

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

For orders placed online please contact us for an accurate shipping quote, sorry for any inconvenience.

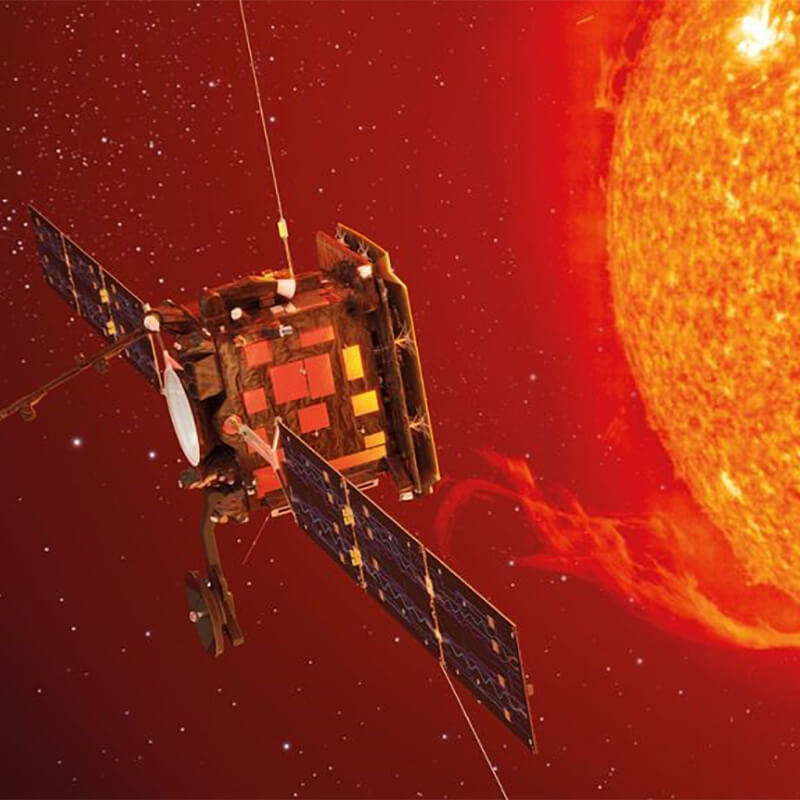

Diamond Coatings’ participation in the NASA ESA Solar Orbiter Collaboration proved to be an important factor in ensuring optimal performance of the ESA NASA Solar Orbiter.

Led by the European Space Agency (ESA) in close cooperation with NASA, the Solar Orbiter ‘s mission is to explore and observe the Sun, its electrical and magnetic fields, solar winds and how they affect earth, as well as collecting data on its atmosphere, outflow of materials and more, as well as offering unprecedented views and delivering the first images of the sun and its polar regions ever – which will hopefully provide scientists with greater insights into what is currently an area of which we have only little understanding.

While the Orbiter will not get as close as NASA’s Parker Probe to the Sun, it will remain within a Sun-facing orbit throughout its entire life of measuring and imaging the solar environment via instrument ports situated at its heat shield’s front.

This orbit means the Solar Orbiter will encounter sunlight that is far more powerful (13 times more, to be precise) than that encountered by Earth on its current orbit – which in turn means it’s going to be extremely HOT!

For spacecrafts, the predominant thought is “white”, and for the Sun, said thought is to “avoid black”. For the Solar Orbiter, things were, however, not quite as “black and white” and subsequently had to be mixed a little.

Extreme temperatures and UV radiation can cause white coatings to gradually change colour, which would affect the Orbiter’s ability to remain cool. The craft therefore had to be coated in a specifically developed pigment (SolarWhite) created from bone.

Resulting in a highly durable carbon/ceramic coating shown to be exceptionally stable under temperature cycling and UV, this pigment also allowed for application of a white silicate layer as an overcoat to provide the stable interface required by the dense ceramic coating to compensate for the difference in thermal expansion between the hot inward facing aluminium side of the craft’s panels and the cold white-coated side facing the vacuum of space.

The original SolarWhite coating was developed in close cooperation between ENBIO and Dublin University College (Ireland). Several of the craft’s SolarWhite components were, however, not facing the Sun, which meant their temperature would drop to lows of as much as -120°C.

At such low temperatures, ceramic’s surface conductivity decreases, resulting in a potential risk of charging- which in turn could eventually lead to electrostatic discharges that could jeopardize electrical systems within the craft.

Stating that the performance of the SolarWhite coating would not have been as intended – which would have put key instruments on the craft at risk – without Diamond Coatings’ help and the application of their conductive ITO coating onto the Stood-Off Radiator Assembly (STORA) panels, Barry Twomey, ENBIO’s CTO, went on to say that “The collaboration was facilitated by Diamond Coating’s flexibility and willingness to support us with our tight deadlines and the scrutiny that goes with such a big project” and that “Although the conductive ITO coating is < 1 µm, it has had a big impact on this new white coating’s performance.”

Check out this video for a great view of our work for the ESA and ENBIO.

We’ve taken our expertise and applied it directly to your journey, developing an Anti-Reflective Film for the Garmin Nav 6

At Diamond Coatings, we provide the foundational transparent conductive coatings that are absolutely essential for capacitive switches

An ITO company fundamentally deals with the precise deposition of Indium Tin Oxide onto various substrates

Glass offers transparency and clear views. But what if it could also conduct electricity, integrating power and data directly into a transparent surface?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.