The Benefits of Coated Glass

Beyond its aesthetic appeal, coated glass offers another set of benefits, significantly enhancing performance, durability, and the overall user experience

All orders placed between December 20th and January 2nd will be processed on January 3rd

What is Indium Tin Oxide Coated Glass and what is it used for?

If you have just searched ‘what is indium tin oxide coated glass’, you are in the right place. What is it used for? We cover that too…

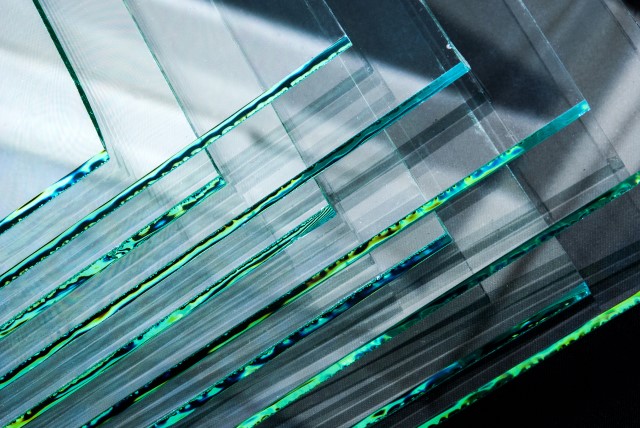

Indium Tin Oxide coated glass

More commonly known as ITO glass, Indium Tin Oxide coated glass allows the surface to be electrically conductive. The neat bit is that ITO is transparent, so a gain of an electrically conductive surface is matched by no loss in clarity. This means that ITO glass is used in a large number of applications, spanning many different industries.

To coat glass with ITO, the procedure needs to take place in an entirely vacuum enclosed area. The most common form of coating is by using the sputtering method.

What is Indium Tin Oxide coated glass used for?

As mentioned above, ITO coated glass is utilised in many different industries and with multiple applications, from display, medical devices and instruments to space exploration.

Probably the most common use is for touchscreen devices, from standard cellphones through to large screen retail displays. The desired touch function is enabled by relying on the skin’s natural electrical conductivity. As the ITO coated glass passes current, a fingertip touch can determine the precise location on a screen, allowing the device to interact with the touch.

In the military and aviation worlds, ITO coated glass screens provide the same as above for many devices, but also offer the option of heating a glass screen. This allows for constant visual clarity, regardless of the environment.

ITO Heaters

In fact, a multitude of vehicles are now using heated ITO windows, including trains and planes. When cockpits in both types of vehicle rely on constant clear views, heated cockpit windows are clearly advantageous.

Other uses of ITO coated glass

Smart windows now utilise ITO coated glass to great effect – literally. The electrically charged glass can offer total screenage, or varying levels of opacity at a flick of a switch (probably on an ITO coated touchscreen device). The privacy benefits here are obvious, but there is also the added bonus of aesthetics… if you do not want curtains or blinds, you don’t need them!

ITO coated glass is also used in the production of OLED screens, cinema projection glass and smart freezer doors (as seen in supermarkets). The medical and R&D industries also use ITO coated glass display equipment as well as ITO coated microscope slides and coverslips.

Diamond Coatings, based in Phoenix, have become a real market leader for ITO coated glass and offer a variety of glass substrates, as well as bespoke options including custom cut holes and printed graphics.

Get in touch…

If you would like to know more about our Indium Tin Oxide coated glass, or any of our other ITO and anti-reflective products, please get in touch with us. You can contact us at the link, or simply email us at sales@diamondcoatings.com. We would be happy to assist with any enquiry.

Beyond its aesthetic appeal, coated glass offers another set of benefits, significantly enhancing performance, durability, and the overall user experience

At Diamond Coatings, we’re not just about providing high-quality coated glass solutions; we’re also committed to manufacturing excellence

Our ITO films provide a transparent and conductive layer that enables seamless touch interaction while maintaining optimal clarity

Advancements in coating technology have led to the development of highly effective scratch-resistant coatings that enhance the durability and longevity of acrylic.

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.